Fluidization is the process of converting granular materials from their solid-state to fluid-like states. It is important to know more about this process if you are in the manufacturing business.

Fluidization

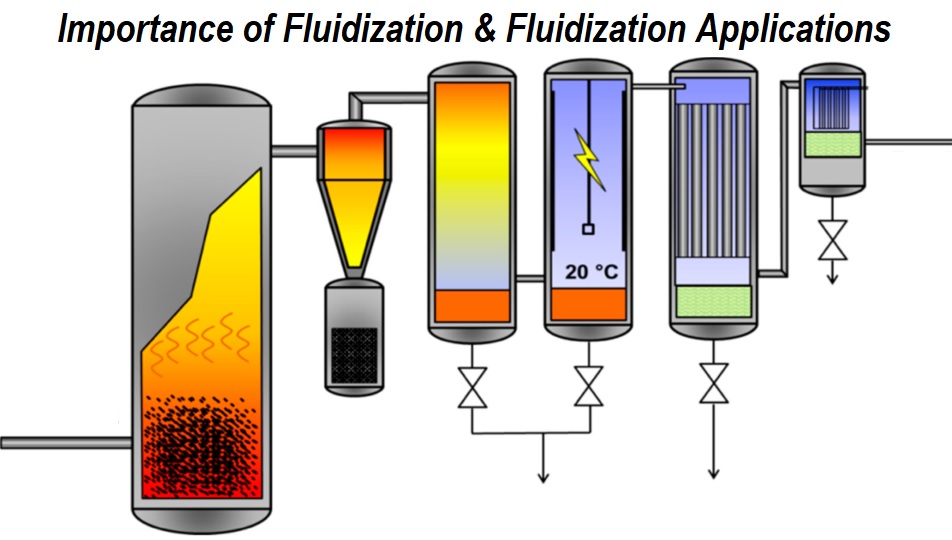

Inside of a fluidizer, gas or liquid particles will be introduced at the bottom of a solid particle layer and move towards the mixture's top. At a low velocity, the materials will remain unchanged. If the velocity is increased, the solid particles begin to separate. At a certain velocity, the pull of gravity will be equal to the liquid's upward force, which results in the solid material being suspended. This is when the particles are said to have been fluidized. If the velocity continues to increase, the solid materials' density will keep decreasing.

After this process, the fluidized solids will behave as if they were a liquid. Like with water, objects with a denser volume will sink through the materials, while those with a lighter volume will float. This is convenient because it allows the material to easily be transported like a liquid, meaning it can travel through pipes rather than over a conveyor belt.

Fluidization Applications

There are many fluidization applications. These areas tend to rely on this mixing technique because it lets solids easily be transferred between substances, gives materials a uniform temperature, and allows for easier transfer of heat between particles. This process was first developed to liquefy coal. However, this was not widely used. The first common use of fluidization occurred in the 1940s when it was used to convert petroleum into gasoline. Since then, it has been used to mix minerals, metals, monomers, polymers, and carbon nanotubes. This makes it popular in many industries, including engineering, food and beverage, hydrometallurgical, water softening, catalysis, and bio-based chemicals.

The technology in this field is still developing. Currently, developers are looking for ways to use this process for chemical looping combustion. Through fluidization, they will be able to manufacture products in a more environmentally friendly manner.

Fluidization is a process that people in manufacturing industries should know about. It is the process of turning solid particles into a liquid-like state. This allows the material to act like a liquid and be transported more easily. Because of the properties it produces, this process has become popular in many industries. Additionally, fluidization technology is still developing, and researchers are attempting to use it to make manufacturing more environmentally friendly.